A major factor to the accelerated effects of climate change is the large-scale release of carbon dioxide into the earth’s atmosphere. One of the main contributors is the burning of fossil fuels to meet the global demands for electrical power. Multiple sources of renewable energy have been created to provide a clean source of electrical power, and one of the leading methods is solar energy.

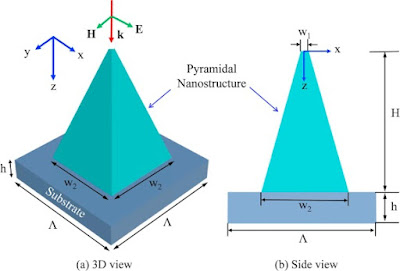

Solar panels harvest energy emitted from the sun, in the form of radiation, and converts it into electrical energy by taking advantage of properties that can be found in semi-conducting metals; most of which are made from silicone (Hossain and Petrovic 2021). This technology has decreased in price by one thousand times since the 1950’s and come with government incentives to help aid their popularity (Hossain and Petrovic 2021). To improve the efficiency of these solar panels, research has been conducted on the effectiveness of pyramid shaped nanostructures on the surface of the panels (Wang et al. 2018). These extremely small structures help to increase the amount of light that is absorbed to where 99.9% of light is being absorbed (Wang et al. 2018). This increase in light absorption could cause a boost in the production of solar energy and aid in the gradual shift from fossil fuel energy sources to renewable energy sources.How does this technology work?

The nanostructures themselves are made from bismuth telluride, a hyperbolic material, which sits atop a thin substrate (Wang et al. 2018). The use of bismuth telluride allows for the structures to absorb 99.9% of solar radiation energy in a larger range than that of similar nanostructures (Wang et al. 2018). The bismuth telluride also provides an increase in the durability of the solar panel by acting as a protective layer (Fu et al. 2019). The pyramid shaped design increases light absorption via a phenomenon called the slow-light effect where the group velocity of the light decreases as the width of the structure increases, causing regions where the group velocity is zero and can be more easily absorbed (Wang et al. 2018). The thin substrate is made from highly reflective materials, like gold and silver, and reflect any non-absorbed light back into the structure to allow it to be absorbed again (Wang et al. 2018). The dimensions and spacing of these structures and optimal dimensions to maximize light absorption have been researched (Wang et al. 2018), but the increased surface area of these structures have been shown to reduce the overall efficiency of the entire solar panel when compared to structures with smaller surface areas (Singh et al. 2018). Reducing the surface area provides a more efficient balance between optical properties and electrical properties within the panel (Cao et al. 2015). However, the gain in efficiency caused by increased light absorption outweigh the losses that come with increased surface area, so this technology still provides higher efficiencies than standard solar panels (Cao et al. 2015) which account for the majority of panels in production to date (Hossain and Petrovic 2021). More research is still necessary to find an optimal balance between structure geometry and electrical properties for the panels to completely optimize efficiency.

How are these nanostructures produced?

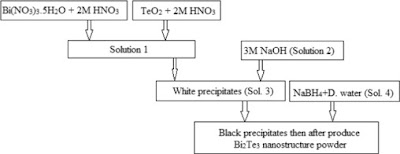

A significant drawback facing this technology is the current process that is used to manufacture the texture on the panels surface is not capable of producing a texture that is effective enough to replace traditional solar panels (Cao et al. 2015). However, research shows how a process using a solvothermal process could provide a potential solution (Mamur et al. 2018). A solvothermal process involves solvents at temperatures past their boiling point which provide improved levels of control over the structures geometry (Shaikh et al. 2020). The geometry is controlled by altering the parameters of the reaction such as temperature, type of solvent, reaction time, surfactant and precursors (Shaikh et al. 2020). This process has been shown to be very viable in the production of bismuth telluride nanostructures in specific while remaining economically beneficial (Mamur et al. 2018).

|

| Figure 2: Schematic of recommended solvothermal process (Mamur et al. 2018) |

This method of production also creates improvements in the thermoelectric performance of the bismuth telluride structure (Mamur et al. 2018). Incorporating this manufacturing process into future solar panels could provide a means of economical mass production of solar panels with bismuth telluride nanostructures. This is going to be necessary if nanostructure solar panels are going to compete with traditional solar technology.

Do these structures provide effective efficiency increases?

Increasing the efficiency of solar panels is extremely important because it allows panels to generate more electrical power. Many different studies have reported different efficiencies when using nanostructure technology. This is due to the fact that different studies use different sized solar panels with different components, materials, measurement conditions, etc. (Mamur et al. 2018). This makes it difficult to compare the results of these reports and come up with an accurate conclusion of how big of an impact the structures have on efficiency. A study comparing different 10-mm-thick solar panels that incorporated different light absorption technologies reported a peak efficiency of around 15.7% when using pyramid shaped nanostructures (Branham et al. 2015). This is compared to and efficiency of 5.3% of a conventional 10-mm-thick solar panel (Branham et al. 2015). This is nearly a threefold increase in efficiency and has the potential for being higher as improvements in structure geometry begin to optimize efficiency. Pyramid structures were also shown to provide higher efficiencies than cone shaped structures for the same 10-mm-thick panels which had an efficiency of 13.7% (Branham et al. 2015). These results cannot be assumed for thicker solar panels, but it provides significant evidence on the vast improvement in solar efficiency. For reference, the highest efficiency achieved among any thickness of silicone solar panel as of 2014 is 25.6% (Green et al. 2014). Achieving an efficiency of 15.7% on a 10mm thick device while remaining economical is a feat that shows remarkable promise for the renewable energy sector and as improvements in nanostructure technology evolve to produce even higher efficiencies, the technology could soon become a standard in solar panel production.

This technology is far from perfect but the increases in efficiency that comes with this nanotechnology provide a great foundation for large scale production of these types of isolar panels. Developing factories that effectively produce these nanostructures via the process of solvothermal synthesis is the key to making these solar panels become the standard in the industry. The increased efficiency in the panels with and low-cost and high precision production would provide a greater incentive for solar energy and has the potential to begin a more rapid shift toward solar renewable energy from follis fuels. This would help to decelerate climate change and provide future generations with a more reliable and long-term energy source.

References

Branham, Matthew S., Wei-Chun Hsu, Selcuk Yerci, James Loomis, Svetlana V. Boriskina, Brittany R. Hoard, Sang Eon Han, and Gang Chen. 2015. “15.7% Efficient 10-Μm-Thick Crystalline Silicon Solar Cells Using Periodic Nanostructures.” Advanced Materials 27 (13): 2182–88. https://doi.org/10.1002/adma.201405511.

Cao, Fang, Kexun Chen, Jingjiao Zhang, Xiaoya Ye, Jianjiang Li, Shuai Zou, and Xiaodong Su. 2015. “Next-Generation Multi-Crystalline Silicon Solar Cells: Diamond-Wire Sawing, Nano-Texture and High Efficiency.” Solar Energy Materials and Solar Cells 141 (October): 132–38. https://doi.org/10.1016/j.solmat.2015.05.030.

Fu, Lin, Yingjian Nie, Bo Li, Ning Li, Bingqiang Cao, and Longwei Yin. 2019. “Bismuth Telluride Interlayer for All‐Inorganic Perovskite Solar Cells with Enhanced Efficiency and Stability.” Solar RRL 3 (12): 1900233. https://doi.org/10.1002/solr.201900233.

Green, Martin A., Keith Emery, Yoshihiro Hishikawa, Wilhelm Warta, and Ewan D. Dunlop. 2014. “Solar Cell Efficiency Tables (Version 44): Solar Cell Efficiency Tables.” Progress in Photovoltaics: Research and Applications 22 (7): 701–10. https://doi.org/10.1002/pip.2525.

Hossain, Eklas, and Slobodan Petrovic. 2021. “Solar Photovoltaics.” In Renewable Energy Crash Course, by Eklas Hossain and Slobodan Petrovic, 69–82. Cham: Springer International Publishing. https://doi.org/10.1007/978-3-030-70049-2_8.

Mamur, Hayati, M.R.A. Bhuiyan, Fatih Korkmaz, and Mustafa Nil. 2018. “A Review on Bismuth Telluride (Bi2Te3) Nanostructure for Thermoelectric Applications.” Renewable and Sustainable Energy Reviews 82 (February): 4159–69. https://doi.org/10.1016/j.rser.2017.10.112.

Shaikh, Shoyebmohamad F., Mohd Ubaidullah, Rajaram S. Mane, and Abdullah M. Al-Enizi. 2020. “Types, Synthesis Methods and Applications of Ferrites.” In Spinel Ferrite Nanostructures for Energy Storage Devices, 51–82. Elsevier. https://doi.org/10.1016/B978-0-12-819237-5.00004-3.

Singh, Prashant, Sanjay K. Srivastava, B. Sivaiah, P. Prathap, and C.M.S. Rauthan. 2018. “Enhanced Photovoltaic Performance of PEDOT:PSS/Si Solar Cells Using Hierarchical Light Trapping Scheme.” Solar Energy 170 (August): 221–33. https://doi.org/10.1016/j.solener.2018.05.048.

Wang, Zhaolong, Zhuomin M. Zhang, Xiaojun Quan, and Ping Cheng. 2018. “A Perfect Absorber Design Using a Natural Hyperbolic Material for Harvesting Solar Energy.” Solar Energy 159 (January): 329–36. https://doi.org/10.1016/j.solener.2017.11.002.

No comments:

Post a Comment